loading pattern in rockwell hardness test|iso 6508 1 2023 pdf : warehouse The deeper a defined indenter penetrates the surface of a specimen with a . Resultado da Search: "lorrana joyce". 11 172,9K. LORRANA JOYCE ( COMPLETO NO TELEGRAM @REALSAVIP ) restam poucas vagas no grupo, adicione o .

{plog:ftitle_list}

6 de set. de 2023 · E a influencer Catarina Paolino, de 21 anos, acaba de provar isso, chegando ao top 1% de criadores mais influentes do OnlyFans em menos de 48 horas, .

The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. 2 Brinell Hardness. The Brinell hardness test involves indenting a material with a hard sphere under a .The deeper a defined indenter penetrates the surface of a specimen with a .

The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .Superficial Rockwell Testing. In this test method, the minor (preload) is always 3 kgf. The major load may be any of the following loads: 15kgf, 30 kgf, or 45 kgf. ASTM E18 contains a listing of all regular Rockwell scales and typical .NISTRecommendedPracticeGuide SpecialPublication960-5 RockwellHardness Measurementof MetallicMaterials U.S.DepartmentofCommerce DonaldL.Evans,Secretary .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

rockwell hardness testing procedure pdf

Static indentation tests: A ball, cone, or pyramid is forced into the sur-face of the metal being tested. The relationship of load to the area or depth of indentation is the measure of hardness, . How It Works. The hardness test is done through a series of pressure tests. An indenting tool, typically a diamond or ball indenter, presses against the material’s surface. After a specific hold time, the load is removed, .1 INTRODUCTION. hen in contact with an indenter under load. Hardness measurements can aid in determining material production characteristics (alloy class and heat treatment), degradation .

minimum plate thickness for ultrasonic testing

The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested. The Rockwell hardness (HR) is then determined from the residual indentation depth, along .The Rockwell hardness test utilizes 1 of 6 different main loads: In total, this gives 30 different Rockwell scales. Each one is characterized by a different combination of indenter type and main load, and is suitable for a particular .II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.Major Load Hardness Values Available Material; HRA: TB-HRA-S: C Diamond: 60kg: HRA60 - HRA84: Steel: HRA: TB-HRA-B: . Superficial Rockwell Hardness Test Blocks - ASTM E-18 and ISO 6508 use, on the other hand, .

rockwell hardness testing guide pdf

Rockwell hardness test, a type of hardness test. Hardness Testing Loads. The hardness testing load is the load (“force”) that is applied to the indenter when pressing into the material being tested. The depth or size of .Brinell Hardness Test. Rockwell Hardness Test. Vickers Hardness Test In general, hardness testing is an indentation test whereby a penetrator of a given material, shape and size is forced into the surface of the material being tested by a given load. The degree of hardness is indicated by the depth penetrated or by the area of resulting impression. Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard product. . As a rule of thumb, using the heaviest load that the material can withstand is advisable as the larger indent will provide the greatest .

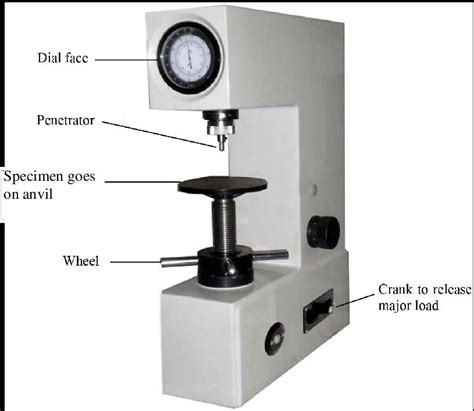

How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) . used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of applications and materials. . a series of measurements are made in a given pattern at a specific . Figure: Rockwell hardness test procedure. The actual test load F 1 is applied in addition to the preload and the indetor penetrates the material with the total force F=F 0 +F1. The test load to be set is taken from table books depending on the indenter and the material to be tested. . The advantage of Rockwell hardness testing is the .

Best Practices for Rockwell Hardness Testing Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years. As a material property, its value and importance cannot be understated; the informationWe offer Rockwell test blocks for all Rockwell Hardness scales for use with a large variety of penetrators and loads. . Grid patterns can be added to our Rockwell test blocks to insure spacing requirements per ASTM E-18. . Hardness: Nominal Ranges Available: Penetrator: Load: 803: HRA Scale : HRA-20 To HRA-84 : C Diamond : 60 Kg : 802: HRB .

ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .

These indenters are unique to the Rockwell hardness test alone. Test Load – The range of loads and the combination of initial minor loads and final major loads also distinguishes the Rockwell method from other test methods. The applied load ranges from 15kgf to 150kgf, where a 3kgf is usually the minor load before applying the major loads. .

In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. The Rockwell hardness of the test piece is calculated by subtracting .

Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: HRE 1/8” diameter tungsten carbide ball indenter, 100 kgf major loadThe Rockwell hardness test procedure involves applying an initial minor load to a sample, followed by a major load, then removing the major load while maintaining the minor one. The depth of indentation caused by the loads determines the hardness value.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). . Advantages of Rockwell Hardness Test. Typically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on all metals, except when .

minimum thickness for durometer test

In the regular (R) Rockwell scale, the Minor Load is is 10 kgf and the Major Load may be 60, 100, or 150 kgf. In the superficial scale (S), the Minor Load is 3 kgf and the Major Load may be 15, 30, or 45 kgf. To ensure accuracy and . Hardness Testing. Wilson Instruments Buehler, with its Wilson line of hardness testers, is the global leader in hardness testing software, equipment and accessories. Buehler is proud to be the proprietor of 100-year old legacy brands including Wilson Instruments, Reicherter, and Wolpert, the innovators and founders of the hardness testing industry.

surface of the workpiece being tested under controlled conditions of load Hardness Testing, 2nd Edition, 06671G . In 1919, the Rockwell test was introduced. It has become, by far, the most popular hardness test in use . each kinematically admissible flow pattern, an upper-bound solution is ob-tained. Hill proposed the slip-line-field .

The most commonly used is the static load intrusion method hardness test, that is, Brinell hardness HB, Rockwell hardness HRA, HRB, HRC, Vickers hardness HV, rubber and plastic Shore hardness HA, HD and other hardness. The value indicates that the surface of the material resists hard objects. The ability to press in.indentation depths under the major load and minor load conditions. The Rockwell hardness test holds immense importance in engineering and manufacturing industries for several reasons. Firstly, it provides a quantitative measure of a material's hardness, which is crucial for . different patterns of results and, consequently, significant .Diamond indenter For Rockwell and Rockwell superficial testing Display mounting bracket Hardness test block 30-35HRC Ball indenter 1/16" Tungsten carbide ball (ø1.5875) Power cord For AC115V Hardness test block 60-65HRC

rockwell hardness test calculation

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . Regular Rockwell Hardness Test where the minor load is 10 kgf and major load is 60 .

The Rockwell Hardness Test is actually one of several tests aimed to gauge a material’s compatibility as a component to an object based on their strength and durability. . Rockwell hardness test is essentially similar to other methods in the sense that strength is gauged through applying load on to a material. How the Rockwell test goes .The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. + 86 755 61301520; [email protected]; Search. Home; . At first, a preliminary test force (preload or minor load) is applied upon the sample with the help of a diamond or ball indenterThe regular Rockwell hardness testing scales use heavier force (load) levels. For these scales, the preliminary force (minor load) level is 10 kgf and the standard total force (load) levels may be 60 kgf, 100 kgf or 150 kgf. The superficial Rockwell hardness testing scales use lighter force (load) levels, typically for use on thinner materials.

minimum wall thickness for ultrasonic testing

missed period negative pregnancy test thick white discharge

WEBAssista Agora. 108 minutos. Uma família está de férias em 1991 quando sua filha adolescente decide fugir com o namorado. Seus pais viajam no tempo até 2022 e veem o .. Mais. Estreia Brasil: 2 de Dezembro de 2022. Outras datas.

loading pattern in rockwell hardness test|iso 6508 1 2023 pdf